Cored wire is to the addition of various additives in liquid steel or iron in solution (deoxidizer, desulfurization agent, modifier, alloy etc.) break into a certain size, and include it into one with arbitrary length of composite material for cold rolled low carbon steel strip. According to the different alloy powder can be divided into: calcium cored wire, wire, silicon calcium barium calcium manganese Silicon Barium calcium aluminum wire, aluminum wire, wire, wire, wire and so on pure calcium calcium. Characteristics: 1, is conducive to adjust and control the content of easily oxidized and trace elements, can greatly improve the yield of alloy, reducing the smelting cost, shorten the smelting time, precise control of composition. 2, to pure liquid steel and some inclusion properties and morphology of the function, improve the quality of molten steel, improve casting state. 3, cored wire inner pump type and free type two, machinery and equipment needed to feed line is simple and reliable, small occupation area, especially the pumping cored wire can adapt to the venue to use a narrow place.

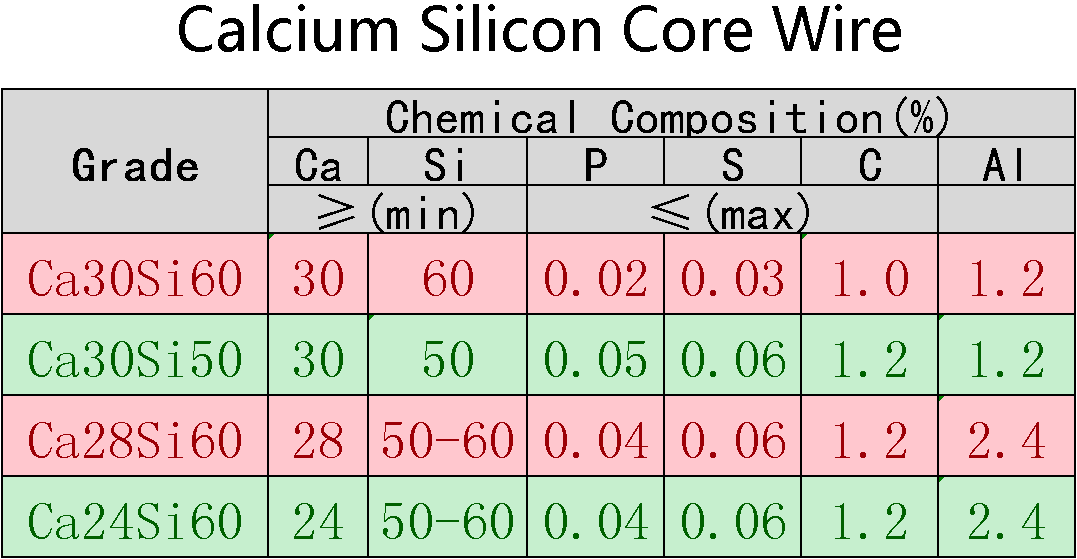

Calcium Silicon Cored Wire

Characteristics

1. Calcium Silicon Cored Wire being propitious to adjust and control the active metal and the content of microelement.

2. Calcium Silicon Cored Wire keep stable of the alloy performance function, reducing steelmaking cost.

3. Calcium Silicon Cored Wire changing the inclusion form to improve the mechanical property.

4. Calcium Silicon Cored Wire facilitate the operation and reduce the operation cost.

Standard

Wire Diameter: 13±0.5mm

Powder weight: 220±10g/m

Maximum coil outside diameter: 1100mm

Minimum coil inside diameter: 600mm

Absolute maximum coil height: 1100mm

Maximum coil weight: 2000 kg

Wire length: 5000±500m

Sheath thickness: 0.35-0.45mm

The specification and packaging can be produce according to customer demand.